Minimizing risk with real-time monitoring of air quality

In construction, mining, manufacturing and similar industries, reliable air quality monitoring is vital to protect workers, minimise environmental impacts and maintain good community relations. This reduces risks including avoiding legal action and reputational damage, not to mention project delay if overseeing authorities halt or restrict your work.

What is air quality monitoring?

Air quality monitoring means continuous assessment of the air to measure the amounts of specific pollutants. Criteria air pollutants is the term for gases or particles for which acceptable levels of exposure can be determined, creating standards.

The potential risks are significant. Some gases can cause cancer, disease of the lungs and respiratory system, and other health effects. Inhaling fine particles such as silica dust can damage lung tissue and cause black lung disease, chronic obstructive pulmonary disease, and silicosis.

Workers are most exposed to these risks, and ensuring their safety is at the heart of such monitoring. Of course, residents must be safe too. They or their elected officials may also take action if exposed to safe but unpleasant experiences such as odors resulting from your activities.

Which activities require air quality monitoring?

A wide variety of commercial activities might generate air pollutants, including the following:

- Construction – a variety of works including excavation, welding and cutting – as well as some materials – produce gasses; and work with stone or concrete can create dangerous respirable particles

- Any manufacturing activity where the same concerns apply

- Mining or quarrying

- Energy activity in areas such as geo-thermal and fuel energy

- Specific industries such as stone cutting

Workers in enclosed areas, such as tunnels, where pollutants may quickly build to dangerous levels, are at higher risk so care needs to be taken to monitor and implement safety measures. Other activities with potential for very high risk include demolition, sandblasting and any work involving the cutting of materials such as concrete.

Understanding the relevant regulation

If you have a specific project in mind and would like support with specification or advice on local requirements, please contact us.

Respirable crystalline silica (RCS)

RCS, or silica dust, is a particularly serious health hazard for workers in construction, mining, and other industries. Crystalline silica is found in sand, rock, asphalt, concrete, brick, block, and mortar. The main danger is inhaling dust created by any grinding, cutting, drilling etc. of these materials, or from sandblasting. Inhaled silica can inflame and scar the lungs, leading to irreversible damage. It is also carcinogenic.

US and Canadian law enforces Permissible Exposure Limits (PELs) which are typically calculated as the averaged exposure expected over an 8-hour shift, meaning continuous, real-time monitoring creates much more relevant information than traditional lab sampling.

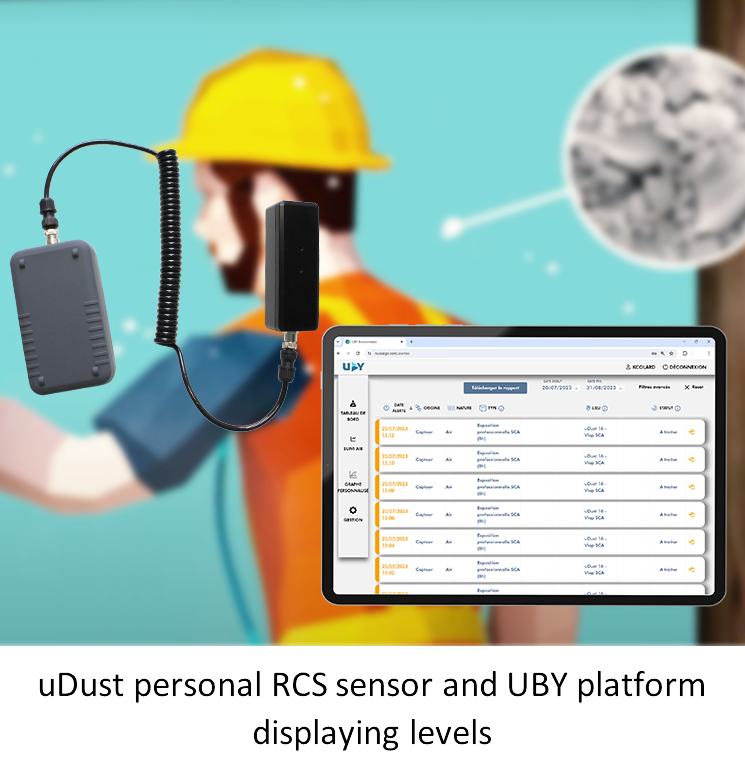

UBY’s detector for silica and other airborne particles, uDust, is a lightweight, wearable solution that sends data in real-time from every sensor to our networked platform.

Our dust monitor uses spectrophotometry to measure and count airborne dust. It complies with the British Standard BS EN‑481 for measuring respirable dust and is mCerts certified. The trained model in this smart sensor uses particle size classification as a signature of material and activity. Smart systems will inform you proactively of the location, nature and intensity of any event, alerts sounding if thresholds you have set are breached. Simple dashboards display short-term (15 minute) exposure events, plus shift exposure as a percentage of permissible limits. A manager can click through to see the name and phone number of an individual worker to speak to them directly.

In Rhode Island, UBY’s air quality and silica sensors were used during tunnel boring on the Pawtucket Tunnel project, to monitor workers for dust exposure, which is a higher risk in this enclosed environment.

Keeping residents as well as workers happy and safe

As well as air quality checks, for the Pawtucket Tunnel operation UBY is also deploying noise and vibration monitoring aimed at avoiding disruption for locals. In other cases, air quality monitoring is itself aimed at community relations.

When multinational Colas Group opened an asphalt plant next to a small, unspoiled Alpine village a few miles from Mont Blanc, they faced particular concerns from local residents.

Engaging with the community proactively, they hosted an open day, explaining to the community that they were deploying UBY Environment’s smart air quality sensors to assess smoke, odors, and other chemical pollutants (a VOC and a PID sensor were used), as well as a weather station and winder dispersion software. The sensors were able to identify pollutants and their concentrations in real time, allowing detailed analysis, plus immediate alerts for threshold breaches.

UBY platforms maintain all data permanently. If you or your client are asked to prove your compliance, full historical information on pollutant levels for every day of your project is available directly. UBY Environment helps projects manage reputational issues, actively demonstrating your strong commitment to corporate social responsibility.

UBY Com combines seamlessly with UBY Environment to help support positive relationships with the community. By providing notice about upcoming disturbances, project teams can engage with the local community and receive feedback from local residents via the same platform. Community reports and sensor data feed into the same real-time database supporting teams to resolve issues fast. The two way communication can be managed through the app, email or SMS, the package also integrates with your own website and social channels. It is customizable, meaning each project can configure which internal and external partners receive what communications.

The value of smarter monitoring

UBY offers a comprehensive range of monitoring solutions for air quality, weather, RCS and much more. Intelligent, proprietary solutions such as UBY Safe and UBY Environment empower you with all relevant information. Benefits include:

- Powerful fundamentals: particulate matter as fine as PM 1 and multiple gases differentiated

- Configurable modes for construction, tunneling, industrial sites, mining, the energy industry and other uses

- Always up to date real-time information

- Multiple individual sensors with all information combining automatically into one resource

- Automated alerts, configurable by you

- Customized, automated reporting on your preferred schedule, with easy configuring of roles and access rights

- Customizable dashboards and reports centered on quick-to-grasp, visual displays for fast, appropriate action

- Unique community relations tools

Monitoring is a proactive step towards safeguarding your workers, protecting the environment, and enhancing community relations. Ensuring a safer and more responsible future for your projects, your reputation, and your community.

Discover how UBY’s real-time air quality monitoring solutions can make a significant impact on your industry. Reach out to us today to learn more about how we can tailor our technology to your specific needs: